News Details

Application Case | Yaskawa Collaborative Robot HC Series Boosts Efficient Production in Factories and Upgrades Palletizing

Release time:

2024-06-17 00:00

In modern industrial production, the application of automation technology is becoming increasingly widespread. Collaborative robots, as an important component of automated production lines, have played a crucial role in many industries.

In modern industrial production, the application of automation technology is becoming increasingly widespread. Collaborative robots, as an important component of automated production lines, have played a crucial role in many industries.

Among them, palletizing technology is widely used in industries such as food, pharmaceuticals, cosmetics, chemicals, and logistics. Especially in repetitive tasks like packing, palletizing, and handling, the application of robots has significantly improved production efficiency and product quality.

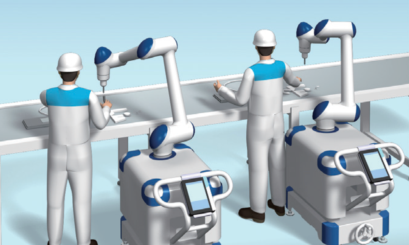

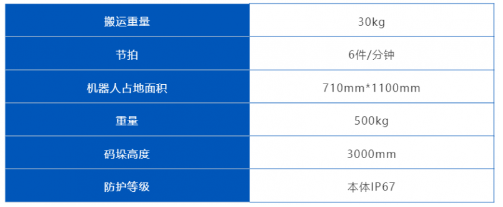

Yaskawa collaborative robots are safe to use and easy to operate. They can automatically perform palletizing tasks in small workspaces shared with workers. Paired with Yaskawa's palletizing software Pallet Builder, it easily generates palletizing programs and effectively improves production efficiency.

As of the end of 2023, Yaskawa Electric has sold a total of 600,000 robot products. Based on the experience from these 600,000 industrial robot sales cases, Yaskawa collaborative robots can utilize industrial robot application software packages, including palletizing, welding, handling, and processing.

Yaskawa collaborative robots enhance palletizing technology with their safer and more flexible performance advantages, saving time, effort, and labor while assisting factories in achieving automation transformation.

The introduction of collaborative robot palletizing technology not only promotes the automation process in production but also brings significant economic benefits and enhances market competitiveness for enterprises. In the future, as technology continues to advance, collaborative robots will play their roles and advantages in more fields.

Next

Related News

What are the typical application scenarios of industrial robots?

Automobile manufacturing: Industrial robots are widely used in the automobile manufacturing process, including tasks such as welding, assembly, painting, dispensing, and inspection.

What are the operating procedures and precautions for welding robots?

A welding robot is an industrial robot that has welding programs preset in its control system, allowing the robot to automatically complete welding tasks.

What are the classifications of welding robots?

The types of welding robots are divided into spot welding robots, arc welding robots, laser welding robots, etc. The most common ones in the market are spot welding robots and arc welding robots.

Current status and development trends of welding robots!

Welding robots are robots that can autonomously perform welding tasks, and they play a crucial role in industrial production.