News Details

What are the operating procedures and precautions for welding robots?

Release time:

2024-10-21 11:34

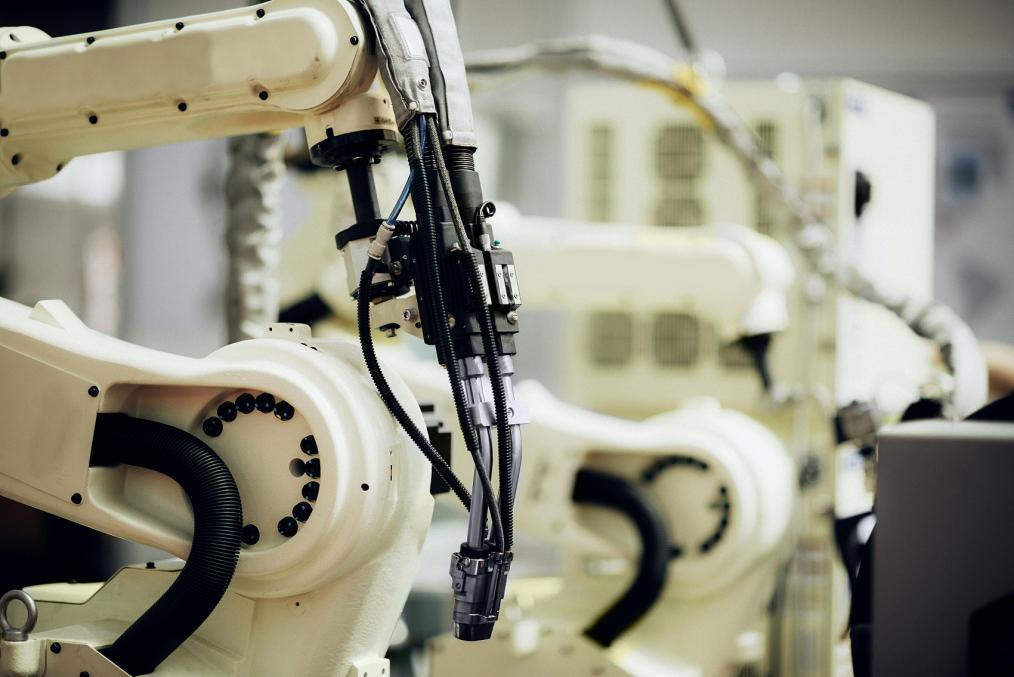

A welding robot is an industrial robot that has welding programs preset in its control system, allowing the robot to automatically complete welding tasks.

The welding robot is an industrial robot that automatically completes welding tasks by pre-setting the welding program into the robot control system. It not only improves production efficiency and reduces production costs but also effectively ensures the quality and stability of the welds.

1. Operation Process of Welding Robots

1. Robot Setup: Before performing welding tasks, the welding robot needs to be set up. This includes setting parameters (such as welding current, welding speed, etc.) and programming the robot's trajectory. After the setup is complete, the program is downloaded to the robot control system.

2. Workpiece Clamping: Install the workpiece that needs to be welded into the fixture, and then secure the fixture to the welding platform.

3. Powering On the Welding Robot: Connect the welding robot to the power supply, press the power button, and start the robot control system.

4. Start Preheating Function: Before welding, preheating treatment is required. This process is very critical as it allows for a more uniform welding temperature, thereby enhancing welding quality. After starting the preheating function, wait for the preheating time to end.

5. Execute Welding Task: After preheating is complete, the robot begins to execute the welding task. The robot works according to the pre-programmed instructions to ensure welding quality and stability.

6. Quality Inspection: After completing the welding task, a quality inspection of the weld seam is necessary. This step is very important because any small issue can affect product quality and stability.

2. Precautions for Operating Welding Robots

1. Safety: Since welding robots generate high-temperature sparks, radiation, splashes, and other hazards during operation, operators must wear appropriate protective gear and ensure that there are no personnel or debris nearby.

2. Robot Programming: Programming of welding robots is very important. During programming, each step must be carefully checked to ensure accurate values and correct programs. If there are programming errors, it may lead to defects in the weld seam or even welding accidents.

3. Workpiece Clamping: Before performing welding operations, workpieces need to be clamped securely and steadily. If the workpiece is not clamped properly, it may lead to misalignment of the weld position or cracking of the weld seam.

4. Welding Power Supply: The welding power supply is a key component of the welding robot and must be regularly inspected and maintained to ensure normal operation while ensuring safety and effective welding results.

In summary, the operation process and precautions for welding robots are very important; correct operation can greatly improve welding quality and efficiency, while incorrect operation may lead to serious consequences.

Related News

What are the typical application scenarios of industrial robots?

Automobile manufacturing: Industrial robots are widely used in the automobile manufacturing process, including tasks such as welding, assembly, painting, dispensing, and inspection.

What are the operating procedures and precautions for welding robots?

A welding robot is an industrial robot that has welding programs preset in its control system, allowing the robot to automatically complete welding tasks.

What are the classifications of welding robots?

The types of welding robots are divided into spot welding robots, arc welding robots, laser welding robots, etc. The most common ones in the market are spot welding robots and arc welding robots.

Current status and development trends of welding robots!

Welding robots are robots that can autonomously perform welding tasks, and they play a crucial role in industrial production.