News Details

The petrochemical industry robots are迎来 the "dawn" moment.

Release time:

2024-02-25 00:00

The petrochemical industry is characterized by the coexistence of technology, risks, and returns, with various processes, equipment, and business models continuously innovating. High temperature, high pressure, and flammable and explosive conditions run through the entire production process.

The petrochemical industry is accompanied by technology, risks, and returns, with various processes, equipment, and business models continuously innovating. High temperature, high pressure, flammable and explosive situations run through the entire production process. Currently, the wave of digitalization is sweeping the globe, and the trend of industrial transformation is unstoppable. Against this backdrop, building a modern petrochemical industry system, writing a new chapter of high-quality development, and seizing the competitive high ground in the industry cannot be separated from the strong empowerment of digital intelligence technology. As one of the core members of digital intelligence technology, robots are increasingly applied in the petrochemical industry and have welcomed their 'dawn' moment.

In recent years, Sinopec has widely laid out innovative applications of robots in response to the frontiers of digital technology and industrial development needs. Focusing on key businesses such as management, production operations, and sales services, it has vigorously promoted the exploration of 'machines replacing humans' in high-risk, high-intensity, and high-load scenarios. This has been developed layer by layer to build a three-dimensional application system for robots that integrates sky and ground, fixed and mobile collaboration, as well as tangible and intangible elements, fully demonstrating green, intelligent, high-end, and safe development.

Drones conduct aerial inspections of leakage accidents; cameras monitor factory dynamics without blind spots; robotic arms pick and position oil barrels; AGVs (automated guided vehicles) autonomously transport petrochemical products; inspection vehicles roam to detect gases in factories; 'pipeline pigs' inspect thousands of miles for damage; fire trucks bravely enter fire scenes to spray water for cooling; customer service machines intelligently answer customer questions; 'Xiangdangdang' promotes automatic certificate generation for accounting; 'large models' engage in extensive discussions... Sinopec's rich business scenarios provide a broad platform for technological advancement, leading the continuous deepening of robot research and application. This builds a strong foundation for Sinopec to create world-class capabilities and move towards global leadership while injecting powerful intelligence into 'securing energy livelihoods'.

This edition's text and images are provided by Xiao Wentao, Tian Yuanwu, Wang Ning, Yu Jia, Shen Zhijun, Zhou Jian, Zhang Yong, Yu Hui, Wang Yuehan, Gao Xianju, Kang Xiaoning, Liu Jingjing, Zheng Haonan.

Robots will become a new engine for growth in the petrochemical industry.

■ What is the current development status of industrial robots in our country? What are the future development trends?

Li Yikai: With continuous technological advancements, the robot industry is developing rapidly worldwide. Especially in recent years, the speed of practical applications of robots has significantly accelerated. Industrial robots, as an important branch of the robot industry, have maintained a leading position over the past few years. According to statistics, our country has been the largest industrial robot market globally for ten consecutive years. Currently, there are over 300 domestic companies engaged in R&D and manufacturing of industrial robots, with nearly ten leading enterprises. In 2023, the number of industrial robots in our country surpassed 1.5 million units and is expected to maintain stable growth over the next three years.

At the beginning of 2023, the Ministry of Industry and Information Technology and other departments issued the 'Implementation Plan for Robot+ Application Action', proposing that by 2025, the density of manufacturing robots will double compared to 2020. The depth and breadth of applications for service robots and special robots will be significantly enhanced. The ability of robots to promote high-quality economic and social development will be noticeably strengthened. Strong policy support will bring broader prospects for robot applications. In the future, intelligence, autonomy, and collaboration will become important development trends for industrial robots.

With advancements in technologies such as machine learning, deep learning, and artificial intelligence, industrial robots can continuously learn and adapt to production environments to improve efficiency and quality. They will possess smarter perception, decision-making, and execution capabilities; more precise positioning and navigation abilities; more flexible posture control; and more efficient human-machine interaction interfaces. This will enable them to better adapt to different scenarios and achieve more refined production.

■ What advantages do robots have in the petrochemical industry? In which fields are they mainly applied?

Li Yikai: Robots can execute tasks with extremely high precision while reducing risks and losses caused by human error. Moreover, the consistency of robot work results across different times and locations is higher as they are not affected by human operation or fatigue. This helps save time and improve production efficiency. In terms of safety, robots can replace humans in hazardous environments or risky operations such as handling toxic substances or working under high temperature and pressure conditions effectively reducing safety and health risks. In data collection and analysis, robots have a natural advantage as they can be equipped with various sensors to collect large amounts of data in real-time for analyzing and optimizing production processes or predicting equipment failures to enhance production efficiency.

Therefore, from upstream exploration and development to midstream refining storage transportation to downstream sales services, robots can be widely applied across various fields in the petrochemical industry. For example: GTI Company in the U.S. developed an automatic burying robot for mechanical seismic detectors that can quickly bury detectors efficiently; Shell produced special operation robots designed to replace humans in hazardous operations within high concentrations of hydrogen sulfide environments; Saudi Aramco developed nano-robots for oil reservoir detection that assist in detecting overlooked oil reserves; Total Energy launched full-size tracked robots specifically designed for hazardous work environments.

■ What roles can robots play in petrochemical engineering construction?

Wang Kehong: Under the background of 'dual carbon', large-scale, intensive, and clean development has become an inevitable trend for the petrochemical industry. The previous labor-intensive organizational model can no longer meet new project construction requirements. Especially against a backdrop of an aging population and rapidly rising labor costs, a major contradiction has emerged in engineering construction: a large demand for skilled workers versus a decreasing number of practitioners in this field year by year. Therefore, replacing human labor with robots and developing smarter robots has also become an inevitable trend.

Taking welding—the most critical aspect of engineering construction—as an example: In recent years, domestic industrial welding robots have seen widespread application primarily using 'positioners + robotic welding', which can achieve single-layer welding at horizontally rotating positions with mature trajectory planning and seam tracking functions but cannot perform vertical welding or multi-layer multi-pass welding. In 2023, there have been new breakthroughs in intelligent welding robot development. In Yangzi Petrochemical's refining structural adjustment project we jointly developed a nine-axis all-position intelligent welding robot with Refining Engineering Group Company Ten that has broader adaptability breaking previous limitations achieving all-position 'one-click' intelligent welding opening a new phase for intelligent pipeline manufacturing while laying a solid foundation for subsequent developments such as head arc seam welding robots bottom welding robots positioners + N-axis robot technical coupling series.

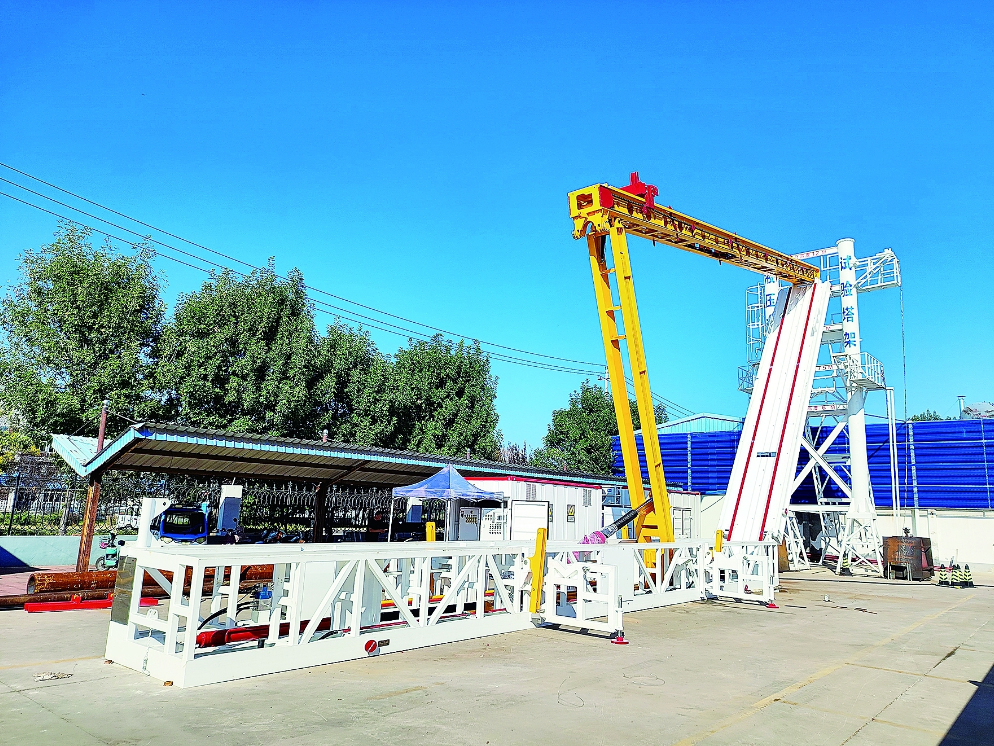

New hydraulic direct push power catwalk.

Employee business card.

■ Job Position: Driller ■ Start Date: November 2023 ■ Main Business: Automatic transportation of drilling pipe columns.

Self-introduction.

I am 'Victory Tiangong', a new hydraulic direct push power catwalk that plays an important role in supporting drilling automation while also being an excellent tool for reducing labor intensity among drilling workers.

As a big guy—12 meters tall and weighing 25 tons, I have a special 'heart' made from a liquid tank by the R&D team, providing me with a continuous surge of power to easily transport drilling pipes such as drill rods, drill collars, and casings back and forth between the ground pipe rack and the drilling platform.

Despite my large size, I am very convenient to operate. With a small remote control, a handle on the assistant driller's chair, and several knobs and switches in my 'heart', operators can choose from these three control methods at will. With just one command, I respond quickly and perform the corresponding actions. I also have a memory function; with a light press of a button, I can automatically record distance, position, and actions, ensuring that the entire transportation process of the drilling column is completed easily and efficiently with one click.

In terms of safety performance, I have various safety protection technologies such as automatic power-off braking, emergency lowering of the transport mechanism during power failure, dual soft and hard limit and interlock for executing mechanisms, hydraulic oil temperature and level alarm self-control, and intrusion alarms in the working area. I can also perform intelligent analysis based on sensor feedback parameters to achieve automatic diagnosis and alarm for abnormal states while controlling the start and stop of related equipment. If necessary, engineers can also conduct remote fault diagnosis and maintenance to ensure normal operation on site.

Currently, there are 21 powerful pieces of equipment like me owned by Sinopec, spread across Dongying, Xinjiang, and other locations. My brothers and I will continue to work hard and provide stable output to reduce the labor intensity of on-site workers and ensure essential safety.

Evaluation

"Victory Tian Gong" new hydraulic direct push power catwalk is a new generation core product of Sinopec's domestically produced automated drilling rigs. From the beginning of its development, it aimed to comprehensively surpass similar products both domestically and internationally. After 170 days of hard work by R&D designers, we completed scheme verification, detailed design, product production, indoor validation, prototype finalization, and on-site application. The new power catwalk has lived up to expectations with an efficiency improvement of over 45% compared to the previous generation product, saving 40% energy. The cycle time for transporting drill rods and drill collars is only 51 seconds, far exceeding the industry standard of 70 seconds. It also has the capability to simultaneously transport 1 to 3 pipe columns, with technical indicators reaching international advanced levels. On-site personnel have experienced the 'wind speed' brought by automation and praised the development of domestic technology.

—— Fu Meng, Team Leader of Scientific Research Design Group at Victory Petroleum Engineering Drilling Technology Research Institute

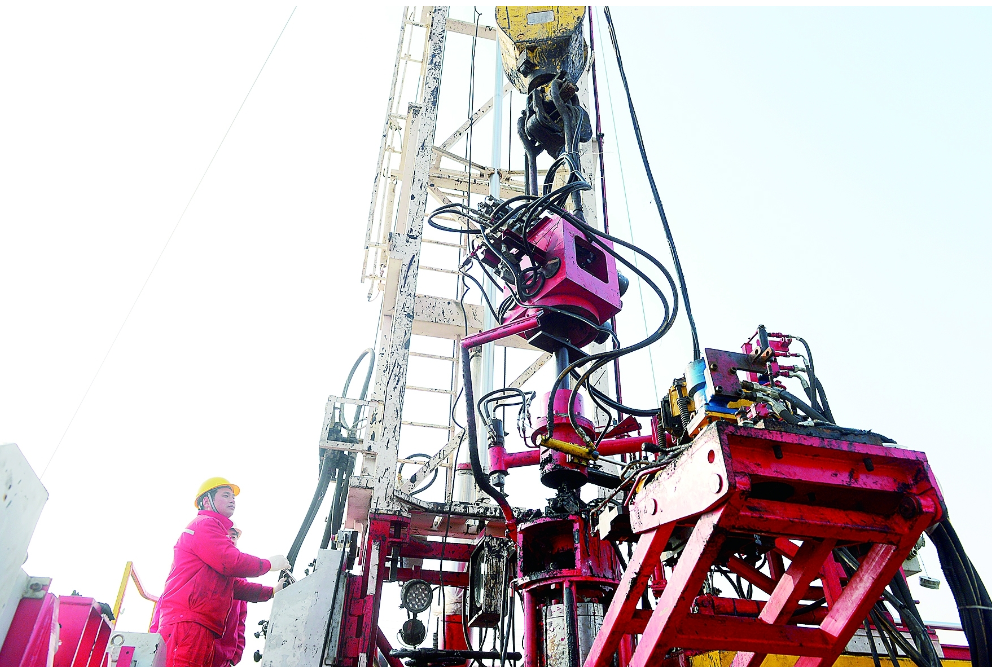

Well Workover Robot

Employee business card.

■ Job Position: Well Workover Worker ■ Start Date: October 2018 ■ Main Business: Performing oil pipe connections and well workover operations

Self-introduction.

I am a well workover robot born in East China Oil & Gas in 2018. I consist of parts such as wellhead operation, pipe suspension, electro-hydraulic control, pipe discharge, and main engine system.

The first generation of me was mainly based on a mechanical arm rotary lifting automation device for well workover operations. I conducted field tests and performance evaluations for automated oil pipe lifting from 2019 to 2023. I have grown robustly during this period and successively achieved automation for lifting oil rods, integrated hydraulic wrenches for pipe rods, one-click start for well control blowout prevention, automated surface pipe discharge for pipe rods, as well as automated drilling grinding and sand washing for single pipes.

Currently, I have advanced to the fourth generation; with just one driller's cooperation, I can complete well workover operations for lifting pipe rods. I can lift 40 oil pipes or 35 oil rods per hour. The on-site operation has transformed from the traditional mode of 'five people one machine', 'two cards one ring', two people switching hanging cards at the wellhead while covered in oil and water into a production mode that replaces humans with machines—one person operating with one-click start in a green and clean manner.

With my participation in well workover operations, my colleagues avoid direct contact with the pipe column; they no longer have to work anxiously under hooks carrying dozens of tons of load. I can handle heavy work, tough tasks, and labor-intensive jobs while reducing my colleagues' labor intensity by 70%. Coupled with online cleaning and detection devices, we achieve 'no liquid spills on the ground; no pollution upon landing' clean production standards while improving safety and environmental protection technology levels in well workover operations. Additionally, I can operate continuously for 24 hours straight; overall operational efficiency has increased by over 20%.

Since I joined the team, well workover operations have become safer and easier; even our tools have become cleaner. Everyone is eager to work alongside me!

Evaluation

In the future, the well workover robot will focus on two areas: first is achieving full automation under any working conditions by developing automated processes for drilling grinding sand washing for single pipes based on power catwalks for lifting oil rods; collaborating with current automated devices for wellhead operations to realize fully automated well workover operations; second is continuously promoting lightweight designs to reduce failure rates in order to address practical issues such as multiple switches in independent modules of current well workover robots being complex sensors that are prone to failure in cold outdoor environments in oil fields as well as significant maintenance workloads later on—overall improving technical indicators for equipment integrity rates in automated well workover devices.

—— Shen Zhongxi, Oil & Gas Engineering Technology Expert at East China Oil & Gas

Nuclear Magnetic Resonance Automatic Sample Injection Collection Integrated Robot

Employee business card.

■ Job Position: Testing Assistant ■ Start Date: April 3rd, 2023 ■ Main Business: Assisting nuclear magnetic resonance analyzers in capturing rock core testing samples

Self-introduction.

Hello everyone! I am an integrated robot for automatic sample injection collection using nuclear magnetic resonance that just joined Victory Oilfield Exploration Development Research Institute in April 2023; I am a 'researcher' in the development laboratory.

My partner is a nuclear magnetic resonance analyzer that possesses quick convenience and accurate quantification capabilities; it can obtain parameters such as moisture content, oil saturation rate, and nuclear magnetic porosity of fresh shale within a short time frame to provide data support for shale oil reserve reporting and 'sweet spot' predictions.

Although testing tasks are assigned to it, rock core samples need to be sent into the machine one by one; after testing is completed, they must be taken out before replacing them with another sample. These auxiliary tasks were originally performed manually by researchers which resulted in low efficiency.

After the establishment of the national-level demonstration area for shale oil in Jiyang Victory region, the number of shale oil rock cores sent daily for testing at Victory Oilfield Exploration Development Research Institute has increased significantly—testing workloads have risen by about three to four times compared to before. Solely relying on manual labor for nuclear magnetic testing can no longer meet research demands.

To find an efficient helper for testing improvements, Victory Oilfield Exploration Development Research Institute collaborated with robot manufacturers and nuclear magnetic equipment manufacturers using AI technology to tailor-make a robotic arm for nuclear magnetic resonance analyzers. Thus I was born.

Although I'm not very tall, I can automatically grab rock core testing samples with a diameter of 2.5 centimeters accurately delivering them into measurement instruments with a measurement accuracy deviation of less than 0.1 millimeters. With me around, researchers have reduced their labor intensity—they only need to handle parameter processing.

Although I only have one hand, I am a "model worker" who tirelessly works every day, increasing the testing work efficiency from 6 times a day in the past to 64 times a day, a tenfold improvement.

Evaluation

Scientific research work places more emphasis on intellectual labor. Only by freeing up both hands can researchers focus more on scientific and technological research. Future scientific research needs to develop towards high-end, technological, and intelligent directions. Not afraid of hardship or fatigue, and having high work efficiency are the biggest characteristics of the integrated robot for automatic sampling collection in nuclear magnetic resonance, which can liberate researchers from mechanical and heavy operations. Its application also inspires us: can other repetitive tasks be replaced by this automated method? Through screening, we have currently adopted fully automated working methods in shale oil saturation testing, front-end sample processing, and other links to further improve work efficiency.

—— Li Fen, Party Branch Secretary of the Development Laboratory of Shengli Oilfield Exploration and Development Research Institute

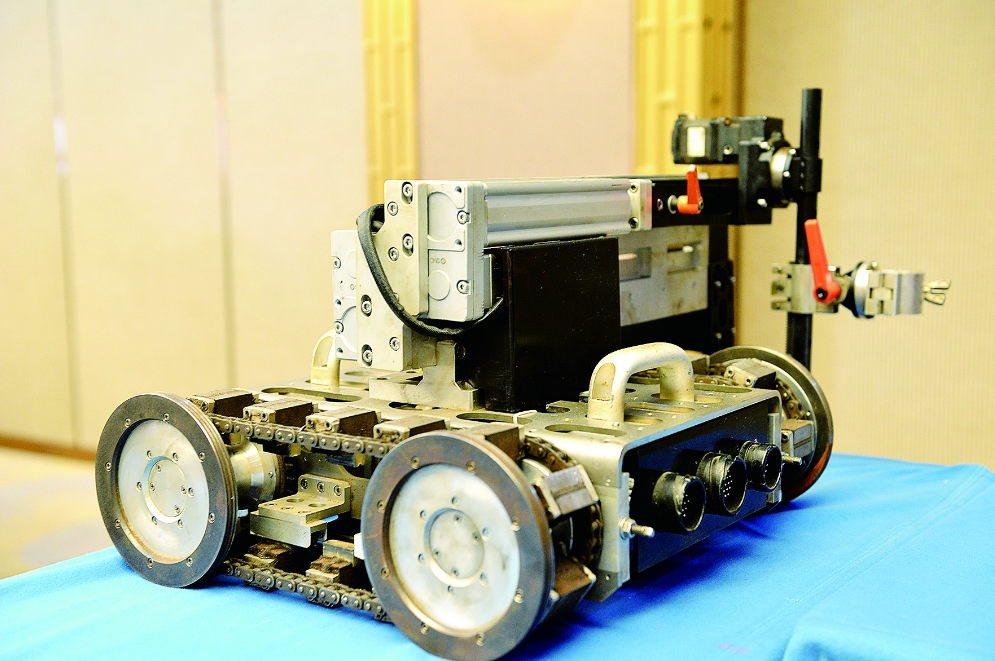

An An (Bionic Intelligent Robot)

Employee business card.

■ Job Position: Safety Inspector ■ Start Date: November 24, 2023 ■ Main Business: Conduct inspections in the pump area of the facility

Self-introduction.

My name is An An, a third-generation bionic intelligent robot developed through over two years of collaboration between Changling Refining and a pump company in Hefei, Anhui. On November 24, 2023, I passed the on-site joint "exam" conducted by experts from the refining and chemical divisions of the group company and successfully obtained the technical qualification for position inspection, becoming a full-time inspector in the pump area of Changling Refining's No. 3 catalytic unit.

Although I may look clumsy, my movements are agile. I can follow procedures to conduct comprehensive inspections of various operational indicators such as shaft temperature and vibration values of pumps in six aspects: listening, touching, checking, seeing, smelling, and comparing. "Listening" relies on monitoring equipment within my body to detect noise or other abnormal sounds during pump operation; "Touching" involves contact detection of vibration values and temperature of pump bearings while storing data; "Checking" uses ultrasonic array imaging to inspect leakage conditions on-site; "Seeing" utilizes visual AI functions to check instrument readings of pumps and upload data; "Smelling" employs a portable toxic and harmful combustible gas detector for real-time scanning of gas leaks in the pump area; "Comparing" uses a digital monitoring platform with pump status monitoring technology to compare operational data and make corresponding diagnoses. In addition, I also possess certain route recognition, obstacle identification, and self-protection functions.

Every day, I conduct inspections along designated routes on time, meticulously collecting and uploading various data such as sound and images. If my battery is low, the interlock system will issue commands at the fastest speed to ensure I return for charging promptly. Since starting my job until now, I have always maintained a "full charge" status, striving to be a reliable safety inspector.

Evaluation

The third-generation bionic intelligent robot has introduced laser radar positioning based on the second generation, equipped with ultrasonic array devices and undergone overall lightweight processing. By incorporating navigation positioning, infrared cameras, gas detection functions, it can quickly collect and analyze information during inspections. Once problems are detected, it will issue alarms promptly. With upgrades to the inspection chassis body, robotic arms, and sensing functions, it has certain explosion-proof capabilities. From a distance, the third-generation bionic intelligent robot resembles a small "baby carriage." Although it may not look impressive, its functions are comprehensive enough to effectively avoid safety hazards caused by human fatigue while maintaining inspection quality. It is an excellent guardian for safe operations in the pump area.

—— Wu Zhiwei, Operator of Changling Refining's No. 3 Catalytic Unit

Xiao Jia (Intelligent Refueling Robot)

Employee business card.

■ Job Position: Refueling Attendant ■ Start Date: August 8, 2023 ■ Main Business: Providing fully automated refueling services

Self-introduction.

With big eyes, sturdy mechanical arms, and red-and-white body paint... On August 8, 2023, I officially joined Guotai Refueling Station in Wuhu City, Anhui Province to provide refueling services for many drivers together with my colleagues. Although my "work experience" is not long, my cool appearance and solid business capabilities have earned me many thumbs up from users.

I was born at Beijing Petroleum. In 2020, Beijing Petroleum actively undertook the new generation artificial intelligence refueling station complete technology research project called "Ten Dragons," establishing Yijia Oil Intelligent Robot Company to begin developing intelligent refueling robots. After six iterations of technological updates, I successfully transformed from laboratory experiments to refueling stations—from water injection tests to fuel injection—from intermittent operation to precise flow—from simple devices to high-end equipment.

Unlike other robots, my body is equipped with multiple advanced devices and has passed explosion-proof certification from the National Explosion-Proof Electrical Product Quality Inspection Center to achieve overall explosion-proof capabilities. My "eyes" consist of an accurate visual recognition system with "star-level" dual cameras paired with a 3D structured light sensor that can accurately capture vehicle information even in dark environments without image recognition blind spots. My "arms" consist of grippers and six-axis explosion-proof robotic arms that can easily perform actions like moving positions, lifting fuel guns, and refueling just like human hands and arms. In simple terms, after receiving a refueling command, my "arms" only need 120 seconds to complete all cover opening and gun insertion operations.

In addition, I possess a powerful "digital brain" that can perceive information such as vehicle distance, fuel cap shape, and fuel nozzle position based on data feedback from my "eyes," issuing commands to my "body" to ensure an orderly refueling service process. The "AI autonomous learning" function allows me to autonomously accumulate recognition data during refueling processes continuously improving algorithms to enhance compatibility with offline vehicle models—achieving human-like thinking and learning.

Currently, I have been employed at refueling stations in cities such as Wuhu in Anhui Province; Changsha in Hunan Province; Nanyang in Henan Province; Xuzhou in Jiangsu Province; and Phoenix in Hunan Province. In the future, I will also appear in other cities to provide considerate energy refueling services for more car owners. Please look forward to my performance!

Evaluation

Intelligence has become an important direction for the development of manufacturing and service industries. Effectively leveraging robots in energy refueling scenarios can not only help traditional energy industries improve quality and efficiency but also open up new fields and tracks for development while shaping new momentum and advantages for growth. The refueling robot we developed possesses advantages such as self-research production systems for core components; systematic service advantages deeply rooted in scenarios; and rapid intelligent advantages through AI autonomous learning. We have currently obtained eight design patents and six utility model patents. Next steps will continue building upon robotic intelligent manufacturing technology as a foundation while gradually expanding into new energy equipment and smart consumer terminal equipment according to a lightweight development model of “overall research design; overall assembly testing,” creating super factories for intelligent manufacturing in fuel sales.

—— Wang Renxiang, Deputy General Manager and R&D Department Manager of Yijia Oil Intelligent Robot Co., Ltd.

Trackless All-Position Crawling Welding Robot

Employee business card.

■ Job Position: Welder ■ Start Date: October 2018

■ Main business: Welding operations at tank circumferences, longitudinal seams, and tank bodies.

Self-introduction.

Without tracks or legs, crawling on the massive storage tank, leaving behind a fish scale-like weld seam — this seemingly clumsy robot is me, the trackless all-position crawling welding robot.

My birth is inseparable from the painstaking efforts of researchers. Since 2017, Wujian Company has collaborated with Boqing Technology to attempt to develop a welding robot suitable for the construction environment of petrochemicals and other fields. After three years of repeated experiments and multiple practices, in January 2019, I officially participated in the construction of the desalination water and condensate water tank area of the Sinopec Refining Project, successfully completing the welding work for six 2000 cubic meter storage tanks' longitudinal seams and some circumferential seams during my first 'trial run.'

In terms of welding for medium and small storage tanks, compared to traditional manual welding, I am lightweight, flexible, and easy to operate. Not only is the preparation time before welding reduced to 20-25 minutes, but I also do not require tracks or guides and can autonomously track weld seams. The welding speed for a single longitudinal seam is 80 mm/min, while for a single circumferential seam it is 300 mm/min, achieving a pass rate of over 98% in one welding session, thus improving welding efficiency by 2 to 3 times.

Recently, during the welding construction of a 5000 cubic meter internal floating roof storage tank at the chemical terminal project in the eastern area of Maoming Port's Bohai New Port District, I showcased my skills once again, receiving positive feedback on the welds I handled. In the future, I will participate in important project welding constructions, allowing more people to recognize me, understand me, and use me, striving to become an indispensable helper in engineering construction as soon as possible.

Evaluation

As the engineering construction industry moves towards an intelligent era, in the future, trackless all-position crawling welding robots will have more applications and promotions in the petroleum and petrochemical fields. We will also strive to implement a '4+1' market service model that provides welding equipment, welding processes, welding materials, welding power sources, and specialized construction teams to achieve a dual harvest of corporate brand and cost-effectiveness.

—— Wang Guorong, Deputy Manager of the Technical Department at Wujian Company

Intelligent Steel Structure Welding Robot

Employee business card.

■ Job Position: Welding Worker ■ Start Date: December 18, 2023

■ Main business: 'One-click' welding construction for steel structure installation.

Self-introduction.

With joint efforts from Shijian Company and researchers from Nanjing University of Science and Technology over ten months of technical breakthroughs, I came into this world and successfully 'started work' at the Qingdao Refining Project.

As an intelligent steel structure welding robot, I integrate cutting-edge technologies from various fields such as visual recognition, reverse reconstruction, trajectory planning, software algorithms, and data applications. These advanced technologies give me exceptional skills: laser vision scanning can accurately determine the position and profile of steel structure weld seams; system software can autonomously plan operating trajectories and welding gun postures. More importantly, I can 'think' and autonomously set welding process parameters. Just press the start button, and the welder can confidently leave everything to me.

With advanced equipment, my work efficiency is exceptionally high; I can accomplish work equivalent to 'four workers,' saving 75% on welder usage. Researchers say that it is precisely because of me that the application scenarios for prefabricated steel structures have been further enriched, transforming traditional steel structure construction from 'two-dimensional' to 'three-dimensional' deep prefabrication. In the future, more companions like head end arc seam robots and 'positioners + N-axis' robots will join the intelligent family of engineering construction.

Evaluation

The intelligent steel structure welding robot features a 'one-click' function that makes operation particularly simple and convenient. Even construction personnel with limited welding experience can learn how to use it in a short time. This is an effective way to ensure welding operation quality in an industry with high personnel turnover. More importantly, compared to traditional welding equipment, not only is the work efficiency extremely high but also smoke emissions and noise are significantly reduced, greatly improving the working environment for welding and protecting employees' physical and mental health.

—— Zhang Simin, Senior Welder at Shijian Company

Little Stone (Intelligent Inspection Robot)

Employee business card.

■ Job Position: Safety Inspector ■ Start Date: September 2022

■ Main business: Daily inspections of LNG receiving station process areas.

Self-introduction.

I am Little Stone, an intelligent inspection robot at the Qingdao LNG receiving station of the Natural Gas Branch. I stand over one meter tall and weigh 360 kilograms; after 'eating a meal,' I can work continuously for six hours.

I am equipped with high-definition visual cameras, laser radars, infrared thermal imaging devices, combustible gas detectors, and other sensor facilities that can locate methane gas points and detect methane concentration while analyzing and identifying leaks within the plant. I can also accurately read local pressure gauges, temperature gauges, and level meters during inspections while transmitting video back so that operational teams can monitor on-site conditions in real-time from the control room.

My job is to utilize three-dimensional laser positioning navigation technology by scanning surrounding objects with laser radar to automatically construct maps and plan inspection routes while patrolling along predetermined paths. I can correct my operating trajectory in real-time; when encountering obstacles, I will actively warn and attempt to navigate around them.

As I slowly 'stroll,' I have become well-acquainted with conditions inside the LNG receiving station; I can easily overcome various harsh weather conditions. Since my employment began, my colleagues' workload has significantly decreased while safety at the LNG receiving station has further improved.

In the future, I will continue learning and enhancing my abilities to improve my judgment and handling capabilities regarding abnormal conditions at LNG receiving stations.

Evaluation

Currently, the Qingdao LNG receiving station of the Natural Gas Branch has completed China's first 'Unmanned Inspection Implementation Guide' for LNG receiving stations under Sinopec's guidance. This has established standards for building unmanned inspection platforms at LNG receiving stations while providing effective guidance and experience for future unmanned inspection constructions. Next steps include continuously exploring unmanned inspection technology applications as well as feasibility studies on replacing manual inspections in certain special areas while advancing towards building a 'Smart LNG Receiving Station.'

—— Wang Jiankun, Deputy Director of Production Operations Department (Technology Information Department) at Qingdao Liquefied Gas Company

(Editor: Wang Ying)

Related News

What are the typical application scenarios of industrial robots?

Automobile manufacturing: Industrial robots are widely used in the automobile manufacturing process, including tasks such as welding, assembly, painting, dispensing, and inspection.

What are the operating procedures and precautions for welding robots?

A welding robot is an industrial robot that has welding programs preset in its control system, allowing the robot to automatically complete welding tasks.

What are the classifications of welding robots?

The types of welding robots are divided into spot welding robots, arc welding robots, laser welding robots, etc. The most common ones in the market are spot welding robots and arc welding robots.

Current status and development trends of welding robots!

Welding robots are robots that can autonomously perform welding tasks, and they play a crucial role in industrial production.